Introduction

Wireless communication systems are indispensable for cargo loading and unloading, transportation, production management, etc. With the expansion of the port scale and the development of port business, the ship loaders of each port have a great request for the wireless communication.

IWAVE team designed this solution special for this kind request.

Detailed Requirements: The clients need to see the live video stream from the Ship loader, please provide wireless communication from ship loader directly to control room.

The solution mainly transmits real-time video and operation data of the ship loader to the operator cabin and to the monitoring room via wireless mesh communication radios from IWAVE company, it also transmits the dynamic loading algorithm, so that the loading efficiency will be improved.

Target of User

Ship loaders in the port

Market Segment

Transportation Industry

Challenge

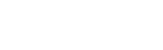

1.The distance from the Ship loader in the section ABC to Control Room is about 900meter-1.1km

2.From the section ABC to the control room, there are not always in line of sight, there are some obstacles and high buildings between this both side that means in none line of sight, so it needs that the wireless communications radio has strong capability in NLOS distance video transmission

3.There are 6 cameras in the ship loader of the section A, the control room and the driver in the operator cabin both need to review the 6 live video streams from the Shipboard area, its needs about 40Mbps transmission data rate at least, so it asks the transmitter has the high bandwidth transmission data rate

4.The communication system is special designed for the port environment, we need to consider the effects from corrosion of seawater and air, so the special shell is required.

Solution

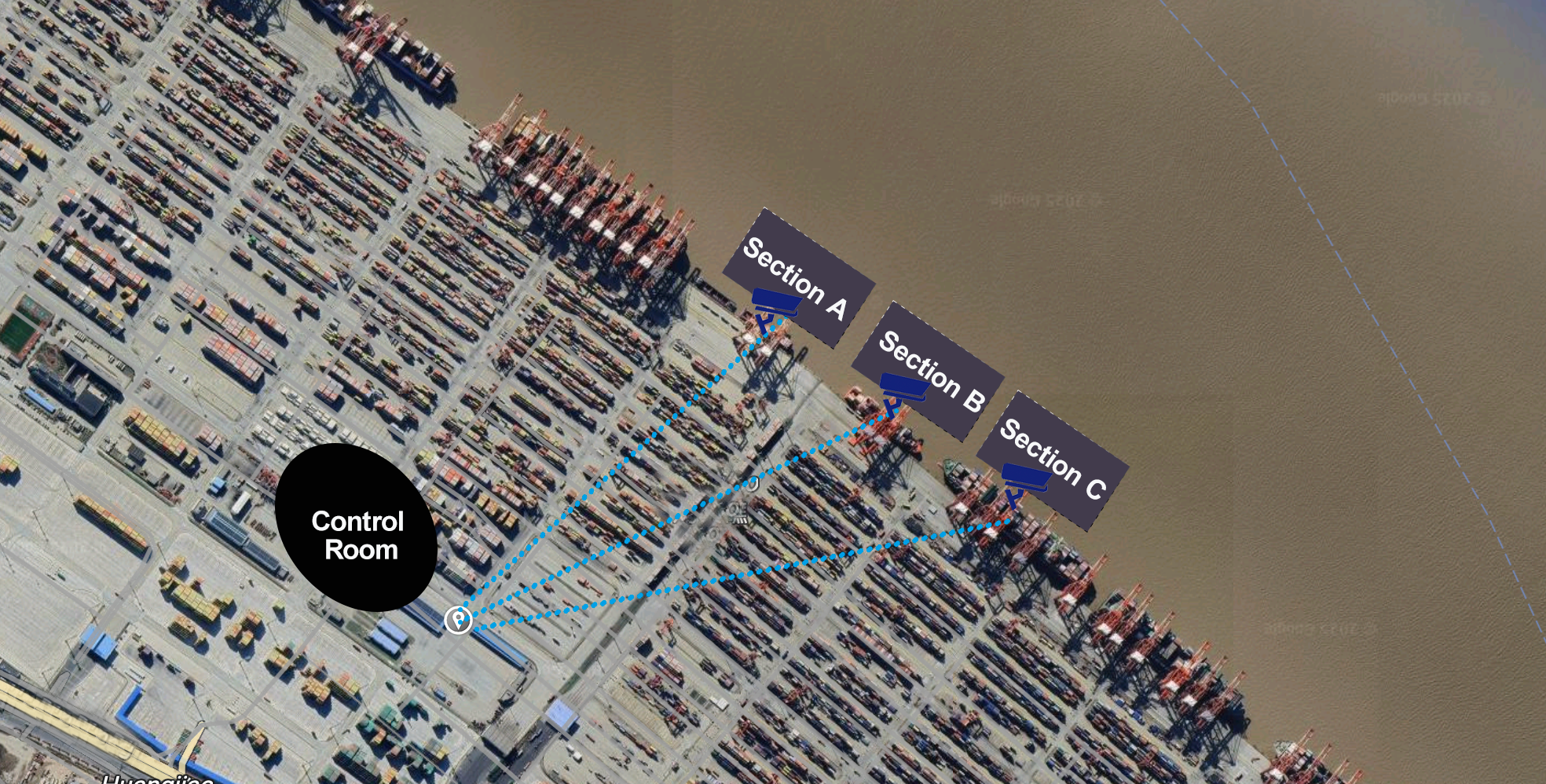

For the first phase, 6 cameras are be installed all over the platform, the POE Switch & NVR are be installed inside Operator Cabin, the cameras will be divided into 2 groups frequency, the transmitters for cameras adopt 1.4Ghz frequency and 600Mhz frequency and the receiver for control room adopt dual band(1.4Ghz+600Mhz) in the Operator Cabin, This can avoid the interference and can meet the requirements of the transmission data rate.

We will use our 10W dual band PtMpt radios FDM-6823FTto transmit the video and data from the cameras to the Operator Cabin, it is a reliable long range video wireless IP radio, it can reach 1-3km none line of sight distance even in this complicated environment

Topology Diagram of the IP Wireless CCTV for the ship loader in the first phase

The ship loader driver can better and more accurately handle loading and unloading operations with real-time video. The wireless transmission device of IWAVE can also transmit control data via IP signal. With the development of automation, it can even automate the loading of goods and automated operations, improving efficiency and accuracy.

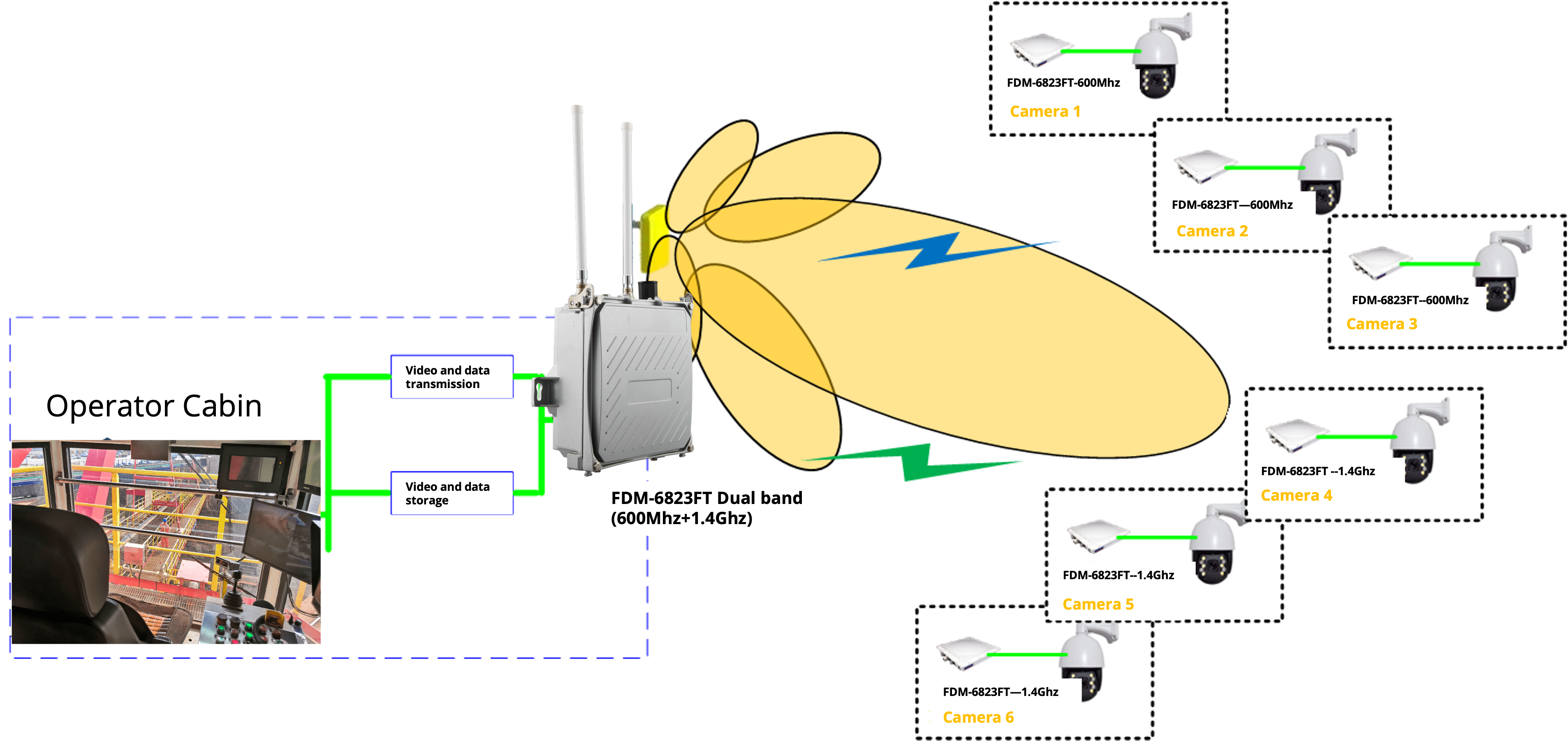

For the second phase,Form the ship loader to the 900meters faraway control room building, we use the FDM-6823FT which is installed in the operator cabin as the transmitter(repeater) and another the FDM-6823FT as the receiver in the control room.

The control room can monitor the working status of the port ship loading and unloading machines in real-time, and the drivers' operating conditions can all be recorded and storage.

Topology Diagram of the IP Wireless commutation system in the second phase

FDM-6823FT provides wireless communication link of HD video, data and serial control data based on IP. It is designed based on CA (Carrier Aggregation), so the transmission data rate up to 120Mbps. The strong transmission data rate capability allows it to provide a stable video transmission link between two objects over a long distance especial in NLOS.

FDM-6823FT automatically negotiates routes with all nodes through the link layer, without manual configuration, plug-to-play. It can quickly build a communication network anytime and anywhere with the characteristics of rapid deployment, high compatibility, low power consumption, and high bandwidth.

Benefits of Solution

Data Analysis and Recording

The monitoring system can record the working data of the crane, including working hours, lifting weight, moving distance, etc., so that management can conduct performance evaluation and optimization.

Video Analysis

Use video analysis technology to automatically identify hook positions, material heights, safety areas and other functions to increase operating efficiency and reduce accident risks.

Video Playback and Retrace

When a problem or accident occurs, the past operating records of the crane can be traced to help with accident investigation and liability investigation.

Safety Training and Education

Conduct safety training and education through video surveillance recordings to help operators understand and improve work practices and reduce potential risks.

Post time: Jul-22-2025